The following is a part of the Concrete Innovations series. This series features products and technologies that have innovated the concrete industry. Today’s article is the first in the series, and it is focused on durability and disaster-proofing. Part two of the series is focused on sustainability, while part three is focused on design.

Durability. When it comes to concrete it seems almost inevitable. After all, there are concrete structures still standing today that were built thousands of years ago. When you consider that early forms of concrete were used to build the pyramids in Egypt, the Great Wall of China, and the Pantheon in Rome, it seems strange to think of concrete as a potentially fragile substance. The millennia-old endurance of these structures is a stark contrast to the deadly collapses of the overpass in Montreal, Quebec, the mall in Elliot Lake, Ontario, and most recently, the overpass in Belo Horizonte, Brazil. Tragedies like these are among the reasons that innovations in the area of concrete durability are so important. Concrete’s strength allows it to protect people from things such as tsunamis and bombs, while also being a superb material for building infrastructure.

Durability Innovation 1: Tsunami Blocking Walls

Being an island nation in the Pacific “Ring of Fire” means that Japan is prone to not only earthquakes, but also to tsunamis. In fact, Japan has many parts of its coastline protected by tsunami barriers. These concrete walls are put in place in an effort to mitigate the amount of damage cause by tsunamis. Rather than striking the populated coast, the tsunami is supposed to hit the seawall. There is some debate regarding the effectiveness of these walls, because oftentimes the waves of a tsunami are higher than the concrete barrier. However, these walls have helped mitigate the damage caused by tsunamis.

The 51 foot high walls in Fudai may have saved the city from the 2011 tsunami

The late mayor of Fudai fought tooth and nail to get a massive sea wall built; he was mocked and opposed at every turn. While most of these concrete barriers are close to 20 feet, the one in Fudai is 51 feet. The “unnecessary” height saved the village from destruction when the 2011 tsunami hit. Nearby towns were wiped out, while there was nearly no damage in Fudai. 250,000 were reported missing or dead two months after the tsunami hit; meanwhile, in Fudai, only one person was reported missing.

The 2011 tsunami that caused much destruction in Japan

Even after the massive wall saved Fudai, residents of other areas affected by the tsunami doubt the value of having walls built. For example, residents of Koizumi are divided over the government’s plan to build walls along 230 miles of coastline. Derisively called the “Great Wall of Japan” by critics, some consider the project to be both a useless expense as well as an eyesore; on the other hand, some residents see the value of this protection and support the government in its endeavours.

Destruction left behind by the tsunami

One of the dangers of building seawalls is that they can lead to a false sense of security. While a wall that is high enough can protect a town from all damage, usually these seawalls are only high enough to lessen the damage caused by tsunami waves. In some areas where these walls existed, people did not bother to evacuate or seek higher ground, believing that they were safe. It is therefore important to note that the walls being built around Japan’s coastline (and elsewhere) are meant to mitigate the damage caused by tsunamis, rather than being tsunami-proof.

Durability Innovation 2: Bomb-proof concrete

Where the Twin Towers once stood, One World Trade Center has been erected using a method that is as symbolic as it is innovative. Researchers have developed a formula that allows them to determine the exact thickness needed for concrete to be bombproof.

One of the main problems associated with explosions is not the amount of pressure in the air – human bodies can generally handle that – but rather, the debris flying through the air. How did researchers solve the problem? By creating concrete that will not break under the pressure caused by a bomb: it is so ductile and flexible that it will become deformed instead. In this way, pieces do not break off and there is no deadly flying debris.

This innovative concrete is essentially a special mixture made from very hard high-performance concrete. When combined with finely meshed reinforced steel, the concrete structure is able to withstand bomb blasts and earthquakes more easily. In addition, the researchers behind this product have developed a formula that allows them to determine the exact thickness of concrete needed for each structure they use it on.

This blast-proof concrete has yet another benefit. Due to its ductility, this concrete is less bulky and more stable than conventional concrete. As previously mentioned, this concrete was largely used in the construction of One World Trade Center: the building’s 20-storey foundation is made from it, and reaches 60 meters underground.

Durability Innovation 3: Concrete that can last 120-1,000 years

Reinforced concrete’s lifespan is expected to be between 50 and 100 years. This is due to the fact that air and water reach the reinforcing steel and cause corrosion (which in turn speeds up the cracking of the concrete). Researchers are always looking for ways to slow the corrosion process, or even to eliminate it all together. With so many components to consider, sometimes researchers come up with very different ways of achieving similar results.

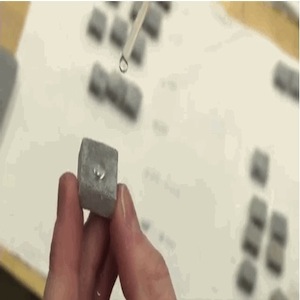

Researchers at the University of Wisconsin-Milwaukee (UWM) have developed a concrete that is less likely to crack than traditional concrete. They achieved this by modifying two properties of concrete. First, concrete is typically porous, which allows water to seep in and eventually reach the reinforcing steel within. This new Superhydrophobic Engineered Cementitious Composite (SECC) has a (microscopically) spiky surface that prevents water from being absorbed. The less water is absorbed, the lower the likelihood of corrosion is.

University of Wisconsin-Milwaukee’s SECC

The second property of concrete that the researchers at UWM modified was concrete’s inflexible nature. By creating adding special fibres to the concrete mix, they’ve created a ductile concrete that can supposedly withstand four times the compression of traditional concrete. These modifications are expected to allow the concrete to last with little to no maintenance for over 100 years.

In Japan, researchers at leading contracting firm Shimizu have developed a new method for minimizing the gaps in concrete. After using a special mix, they wrap the hardened concrete in polyethylene sheets for six months. This prevents much of the water from evaporating, which lessens the opportunity for spaces to form inside the concrete. After six months, the volume gaps have been reduced by up to 75%. Shimizu claims that this process can extend the concrete’s lifespan to around 1,000 years.

Durability Innovation 4: Self-Healing Concrete

Researchers at the University of Bath took an entirely different approach in their attempt to increase the durability of concrete. Rather than preventing cracks, the researchers have created a concrete that will heal its own cracks as they occur. If it sounds like the concrete might be alive, that’s because in a way, it is. The concrete contains micro-capsules filled with bacteria. When cracks form, water and air have a chance to reach these micro-capsules. Once that happens, the bacteria germinate and produce limestone. This limestone will fill the crack, preventing water and air from reaching the reinforcing steel.

Could corroded concrete be a thing of the past with Bath University’s new concrete?

Not only will these bacteria fill the cracks by multiplying, but they will prevent corrosion in another way. This multiplication process requires oxygen; therefore the bacteria will block oxygen and water from entering, while using up any oxygen that had already come through.

Researchers at Newcastle University have also been experimenting with bacteria and concrete. However, rather than filling cracks automatically, this product (called “BacillaFilla”) is meant to fix cracks that have already occurred. Considering the rapidly deteriorating state of infrastructure in Canada, the US, and around the world, BacillaFilla has a high potential for usefulness. The researchers have genetically modified the bacteria in such a way that it only germinates when it comes into contact with concrete. From there, the bacteria travels down the cracks until they reach the end of it; once the end of the crack has been reached, the bacteria begin to clump up.

In the future, cracks like these could be repaired with BacillaFilla

This clumping signals to the bacteria that they have reached their destination and can now become one of three things: cells that produce calcium carbonate, cells that can act as reinforcing fibres, or cells that produce a binding agent. When there three types of cells combine, they harden to the same strength as the concrete that surrounds them. On top of all the above genetic modifications, the researchers added a self-destruct gene. This causes the bacteria that fail to germinate to be unable to survive.

Sources:

Tsunami Blocking Walls

The Guardian

The Telegraph

Daily Mail

Bomb-Proof Concrete

Laboratory Equipment

120-1,000 Year-Old Concrete

Architecture and Design

Nikkei

Self-Healing Concrete

Gizmag

Phys Org

Gizmag

Fonte: www.giatecscientific.com